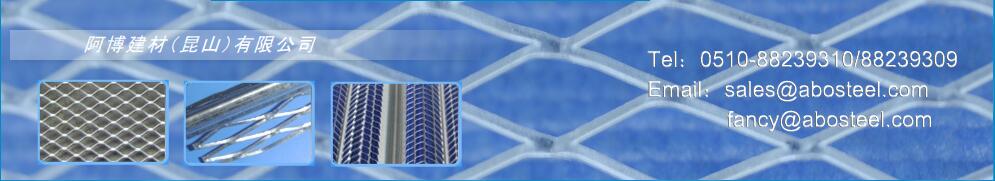

Paper-faced metal beads

Paper-faced drywall trims

Paper faced metal drywall beads and trims

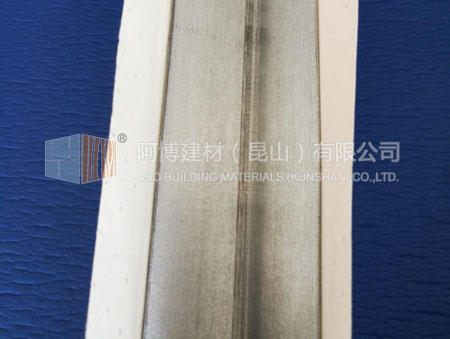

Paper face metal inside corner beads

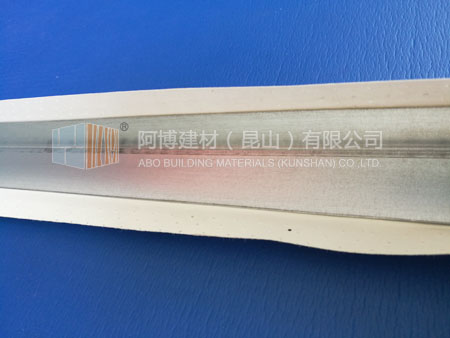

Tape on outside corner

Description

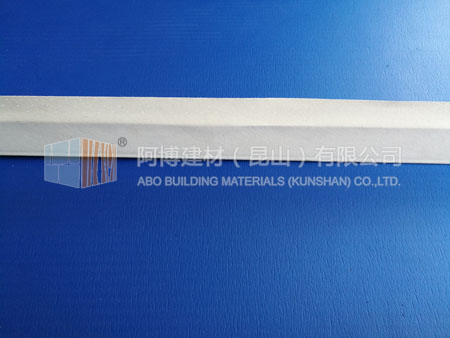

Paper-Faced Metal Corner Bead is produced with strong, bleached kraft paper tape that is laminated to a sturdy, rust-resistant metal beads.

Strong paper tape prevent cracking caused by movement or shrinkage of framing.

Galvanized metal have maximum strength and protection for corners and increased rust resistance.

It resists edge cracking and chipping, resulting in corners that stay beautiful despite normal building movement and everyday wear-and-tear.

The paper-faced angle beads can be installed without fasteners by embedding into joint compound.

Material

0.3-0.7mm Galvanized sheetbleached kraft

Specification

Type

|

Paper faced metal beads dimensions

|

||||

A (mm) |

B (mm) |

C (mm) |

D (mm) |

Length(inch) |

|

AB-PAB-6’ |

18 |

27 |

27 |

18 |

6’ |

AB-PAB-8’ |

18 |

27 |

27 |

18 |

8’ |

AB-PAB-9’ |

18 |

27 |

27 |

18 |

9’ |

AB-PAB-10’ |

18 |

27 |

27 |

18 |

10’ |

| All dimensions can be customized according to your requirements. | |||||

Products Benefits

1. Compare ABO Building paper faced angle beads to metal corner beads, installed 38% faster than traditional metal beads.2. The paper faced corner beads requires less joint compound, the crew increased their productivity, which save a significant amount in labor cost.

3. The paper faced angle beads doesn’t require nails and screws, it saves money and cost.

4. Backed by a limited-lifetime, no edge-crack warranty for long-term performance.

5. Offers high-quality straight lines for interior construction features.

6. Available in a variety of profiles to maximize design flexibility.

7. Durable paper facing reduces paint and compound chipping.

Applications

Paper-Faced Corner Bead features traditional styled corners to provide clean, sharp lines and give architectural details such as paint transitions and step bulkheads a more dramatic look.Recommended installation method

1. Outside corners apply a band of joint compound 100mm wide and 6mm thick to each side of the corner.2. Cut the paper faced angle beads to length required and position over the joint compound allow 1/2” at bottom for expansion and contraction of framing members.

3. Embed the corner beads firmly into the compound. Using a small finishing knife, wipe the excess compound from under the paper to eliminate all air bubbles. Allow to dry.

4. Using a large finishing knife, apply compound in a band about 200mm wide from the nose of the beads beyond the paper edge.

5. Level compound by drawing the knife along the beads with one edge of the blade riding on the nose and the other on the surface of the board.

6. Apply second coat one previous coat is dry, feather the edge of each coat about 50mm beyond the preceding coat.

Storage:

Avoid bending or other damage and store in a dry place protected from moisture, store away from acids and incompatible materials.