Architrave beads

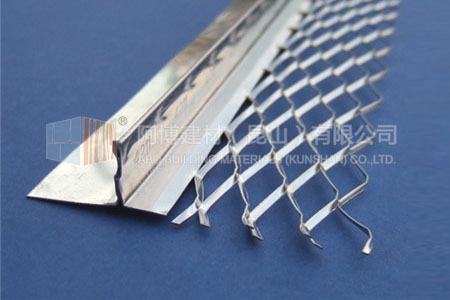

Architrave feature bead

Architrave beads

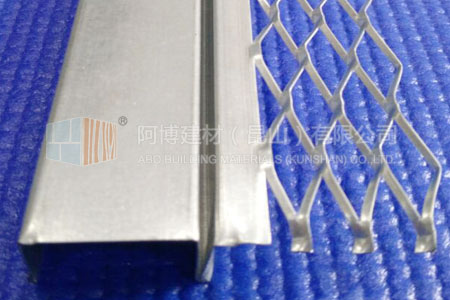

Architrave beads without flange

Architrave plaster bead

Architrave beads With Return

Description

Gives a shadow line decorative effect for aesthetic purposes and creates a clean division between varying wall finishes. Galvanized (internal use) and stainless steel (external use) Architrave Feature Beads used for decorative purposes to give a shadow between different walls finishes (i.e. Wall and ceiling or door and window reveals). It can also be used to act as a neat divide between differing wall finishes.Available with or without a return flange-(engaging or abuuting).

Specification

Reference |

Width(mm) |

Length(mm) |

Plaster thickness(mm) |

AB-ABC10 |

10 |

3000

|

10/13

|

AB-ARC15 |

15 |

||

AB-ARC20 |

20 |

||

AB-ARC23 |

23 |

||

AB-ARC25 |

25 |

||

AB-ARC27 |

27 |

||

AB-ARW101 |

10 |

||

AB-ARWO13 |

13 |

||

AB-ARWO15 |

15 |

||

AB-ARWO20 |

20 |

||

AB-ARWO25 |

25 |

||

| Note: AB-ARC refers to ABO Architrave Bead Without Flange; All dimensions can be adjusted according to the customer requirements; |

|||

Applications

Provides clean, neat edges to 2 coat plaster and render work at opening or abutments onto other wall or ceiling finishes. Ensuring protection against chips, cracks and impact damage. The bead firmly inserts into the plaster and offers a straight line and reinforce to let it more firm.Storage and protection

The installation of ABO beads shoule be in accordance with BS5492:1990(internal) and BS 5492:1991(external).Beads should be fixed using plaster dabs or mechanical fixing at a maximum of 600mm intervals. Beads can also be fixed to lath sheets by the use of galvanised or stainless steel tye wire.

Use tinsnips to cut the bead wings and a fine toothed saw to cut the nosing.

Care should be taken to ensure that steel beads are kept dry, and stroed and handled in a way to prevent distortion and general damage, especially to the galvanized coating. This means storing them off the ground on a flat surface.

The risk of corrosion in galvanised beads will normally only become apparent during the initial drying out period of the plaster, which should be kept to an absolute minimum (maximum5-7days), and subsequently during periods of heavy condensation and dampness.

All metal comppnets used in a particular installation must be of all the same material type, i.e stainless fixings with stainless beads/sheets and galvanised fixings for galvanised beads and sheets.